We are thrilled to share the progress made at the Barcelona Supercomputing Center (BSC) on developing a comprehensive Digital Twin system for steel reheating furnaces, as part of the TWINGHY Project — a collaborative effort with Celsa Group, RWTH Aachen University, Swerim, and other European partners.

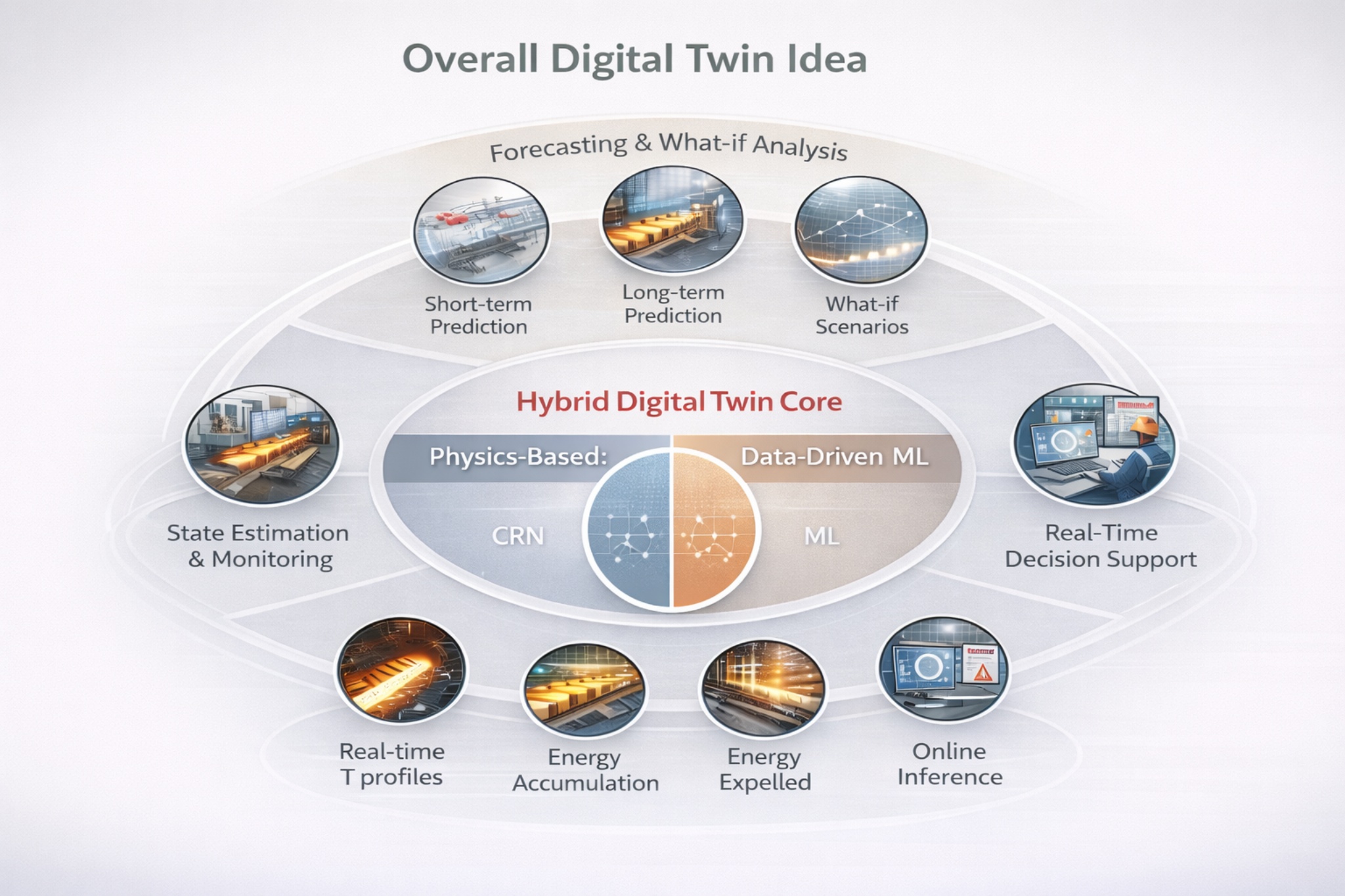

Steel reheating furnaces present a fascinating engineering challenge. These massive industrial assets must precisely heat billets to temperatures exceeding 1200°C while simultaneously optimizing energy consumption, maintaining temperature uniformity across eight heating zones, meeting production throughput requirements, and reducing carbon emissions. To address this, our work proposes a new strategy that brings together artificial intelligence and physics-based modelling through a novel physics-informed neural network architecture that respects the fundamental thermodynamics of furnace operation.

Rather than treating the furnace as a black box, we designed a staged model that follows the actual gas flow through the system, cascading predictions from soaking zones through heating zones to pre-heating zones. The model employs multi-scale temporal encoding using dilated convolutional networks combined with attention mechanisms, allowing it to capture both the rapid switching patterns of burners and the slow thermal dynamics of the refractory mass. We also implemented separate heating and cooling pathways with learned thermal inertia, ensuring that predictions remain within physically realistic bounds — after all, the furnace simply cannot change temperature faster than thermodynamics allows.

All of these capabilities come together in an interactive web-based dashboard that provides plant operators with real-time energy balance visualization, interactive burner schedule optimization, temperature prediction and monitoring, and configurable analysis tools. The interface transforms complex AI outputs into actionable insights that operators can trust and understand.